Product description

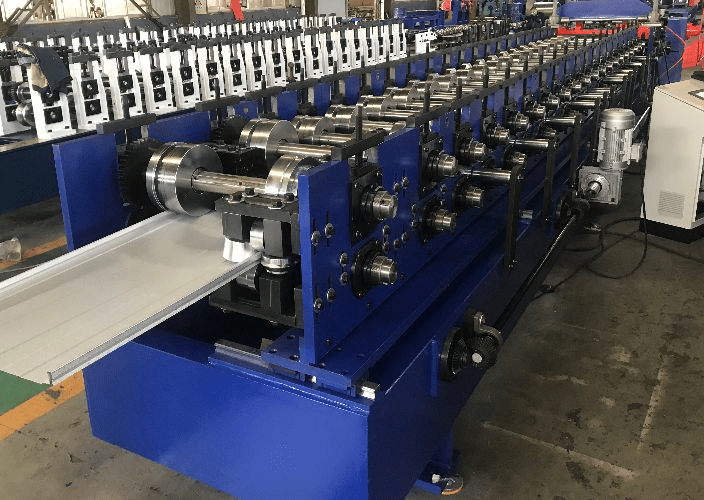

Features of C Purlin Roll Forming Machine

The C shaped purlin formed by C purlin roll forming machine has excellent anti-bending property and are easy to install. Machine adopt cast iron structure, which will increase the strength of the machine.

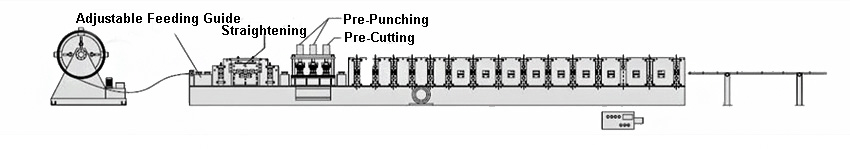

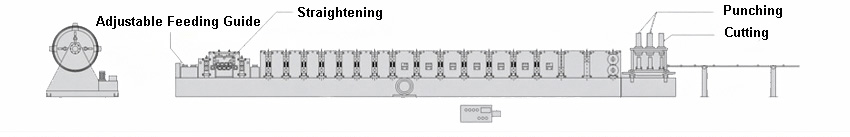

The processing of Punching & Cutting has different type for choosing: Post-Punching & Post-Cutting, Pre-Punching & Post Cutting, Pre-Punching & Pre-Cutting.

Applications of C Purlin Roll Forming Machine

The finished products are widely used as the supporter of roof and wall in large-scale and mid-scale construction, such as factory, warehouse, garage, exhibition center, cinema, theatre, garden and so on.

Process Flow of C Purlin Roll Forming Machine

Uncoiler — Feeding — Straightening — Pre-punching — Pre-cutting — Roll Forming — Exit Rack

Uncoiler — Feeding — Straightening — Roll Forming — Post Punching — Post Cutting — Exit Rack

Machine Configurations of C Purlin Roll Forming Machine

| 1. Hydraulic Uncoiler | 2. Feeding Device |

| 3. Straightening | 4. Roll Forming Machine |

| 5. Punching | 6. Cutting |

| 7. PLC Control System | 8. Exit Rack |

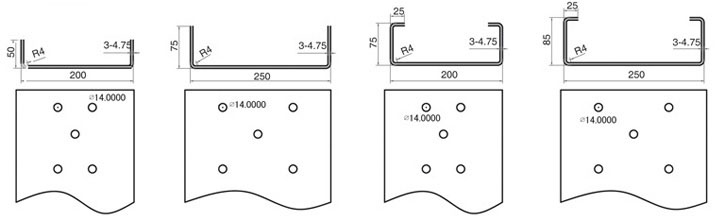

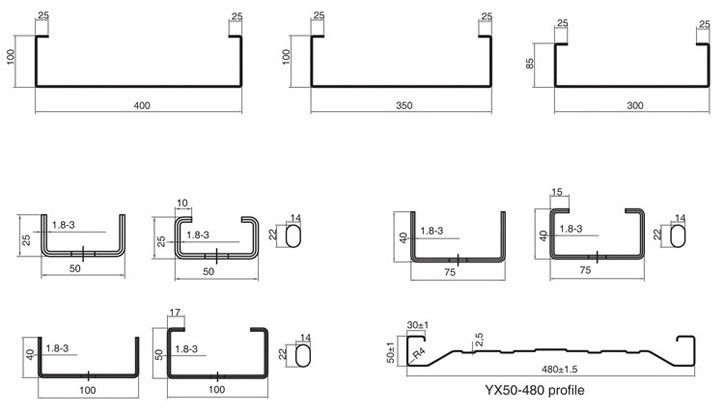

Profile Drawings for Reference

Reviews

There are no reviews yet.