Product description

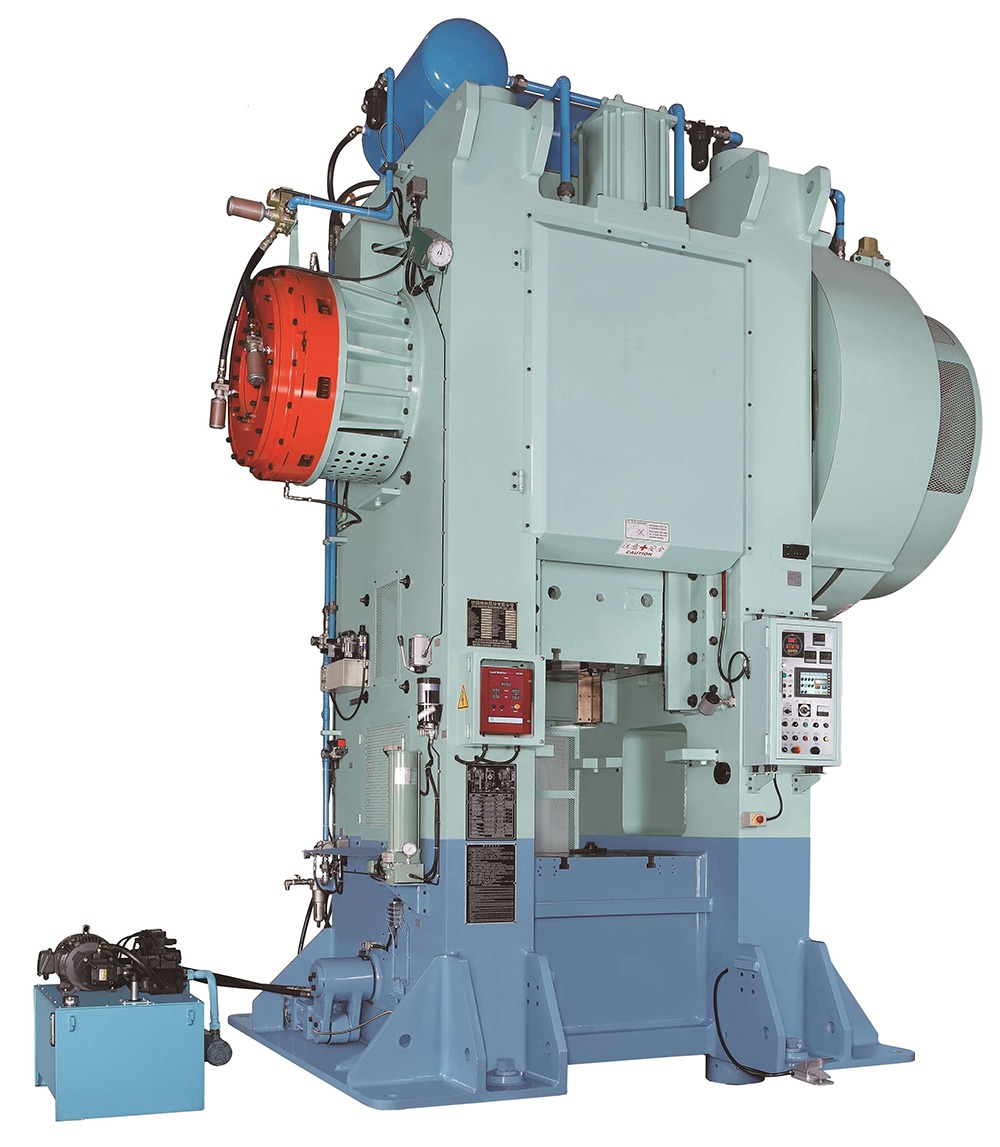

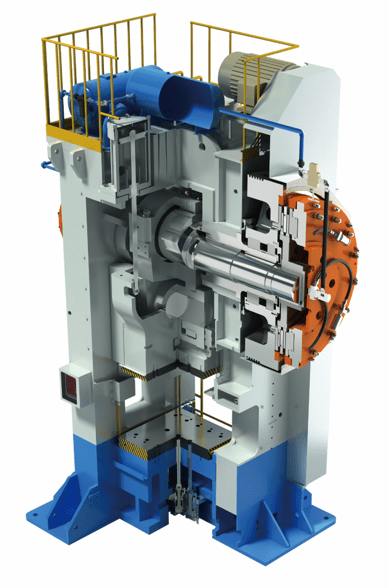

High Speed Forging Press is suitable for processing forgings needed in hand tools, autos, motorcycles, bicycles,trains, ships, machine tools, textile machines,woodwork machines, conveying equipment, mining machinery, hardware parts, etc. It’s an indispensable machinery equipment for modernized forging plants,because it can produce precision forgings that can meet customer’s quality and delivery requirements.The machine is a sharp production tool for forging plants.

| Advantages | Design |

| High Production Efficiency Longer Die Life | High Stroke Speed Ram and Bed Ejection Design |

| High Precision Forging Parts | Extended Eight-Faced Guide Ways |

| Stable Product Quality | Unique Connecting Rod Design |

| High Safety Standard | PLC Multi Circuit Loop System, |

| Ensure the Safety for Operator and Machine | Micro Computer Load Meter |

| Fulfill the Environmental Protection Standards | Flywheel Transmission Has Low Noise Decibel |

| Easy to MaintenanceEasy to Operate | Well Designed Lubrication System |

| Mold Stuck Releasing System | |

| Iron, Aluminum, Copper and Titanium Alloys are Practicable in forging | Longer Stroke Distance Shut Height is adjustable |

Specification

| Item / Model | Unit | FP-400 | FP-600 | FP-800 | FP-1000 |

| (400 TONS) | (600 TONS) | (800 TONS) | (1000 TONS) | ||

| Capacity | Tons | 400 | 600 | 800 | 1000 |

| Stroke of ram | mm | 175 | 200 | 250 | 250 |

| Adjustment of ram | mm | 10 | 10 | 10 | 10 |

| Number of stroke | Spm | 100 | 95 | 85 | 85 |

| Work number of stroke | Spm | 18 | 18 | 16 | 16 |

| Shut height | mm | 505 | 650 | 650 | 800 |

| Rated tonnage point | mm | 5 | 5 | 5 | 5 |

| (L-R & F-B) Ram dimension | mm | 590*650 | 690*630 | 800*790 | 940*850 |

| (L-R & F-B) Table dimension | mm | 770*840 | 880*880 | 980*1000 | 1100*1050 |

| (L-R & F-B) Side window | mm | 450*450 | 500*500 | 600*600 | 700*650 |

| Main motor | Kwxp | 30kw*8p | 37kw*8p | 45kw*8p | 55kw*8p |

| Ram of adjustment motor | Kwxp | 0.4kw*4p | 0.4kw*4p | 0.75kw*4p | 0.75kw*4p |

| Motor of lubrication | Kwxp | 0.1kw*4p | 0.1kw*4p | 0.1kw*4p | 0.1kw*4p |

| Ejector in the ram | Tons-mm | 6Ton-20mm | 6Ton-20mm | 6Ton-30mm | 2.5×3=7.5Ton-30mm |

| Ejector in the table | Tons-mm | 12Ton-40mm | 12Ton-40mm | 12Ton-40mm | 8×3=24Ton-40mm |

| Ejector hydraulic oil motor | Kwxp | 5.5kw*6P | 5.5kw*6P | 5.5kw*6P | 7.5kw*6P |

| Working number-distance | Number-mm | 1 | 1 | 1 | 3-200 |

| Air pressure | kg/cm2 | 5 | 5 | 5 | 5 |

| Press weight | kg | 29,500 | 40,000 | 52,000 | 72,000 |

| (L*W*H*) Press dimension | mm | 2100*3360*4260 | 2260*3550*4970 | 2700*4000*5300 | 2800*4300*5800 |

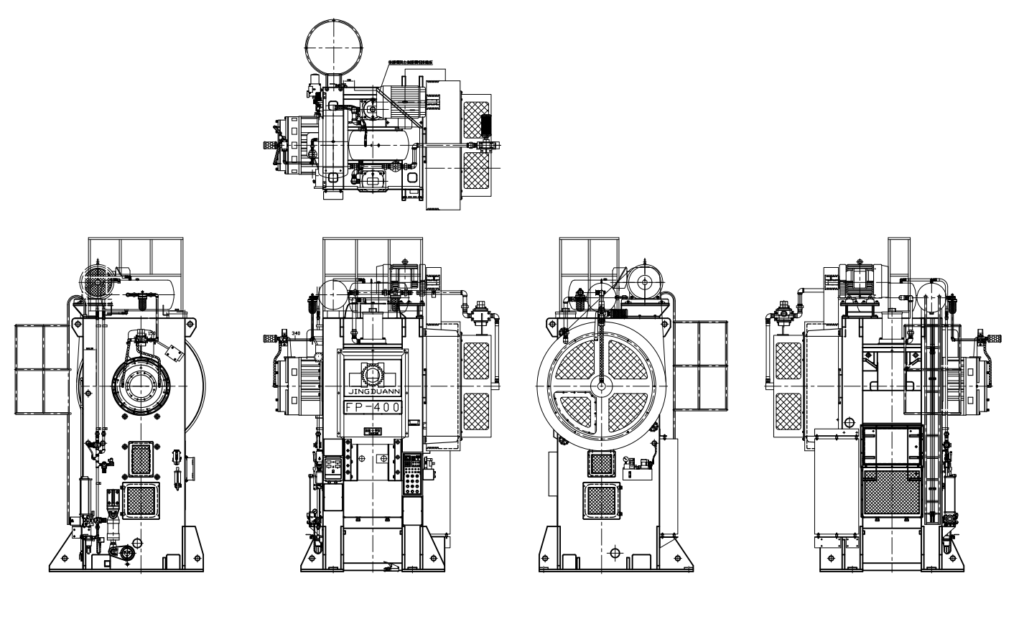

Machine layout design

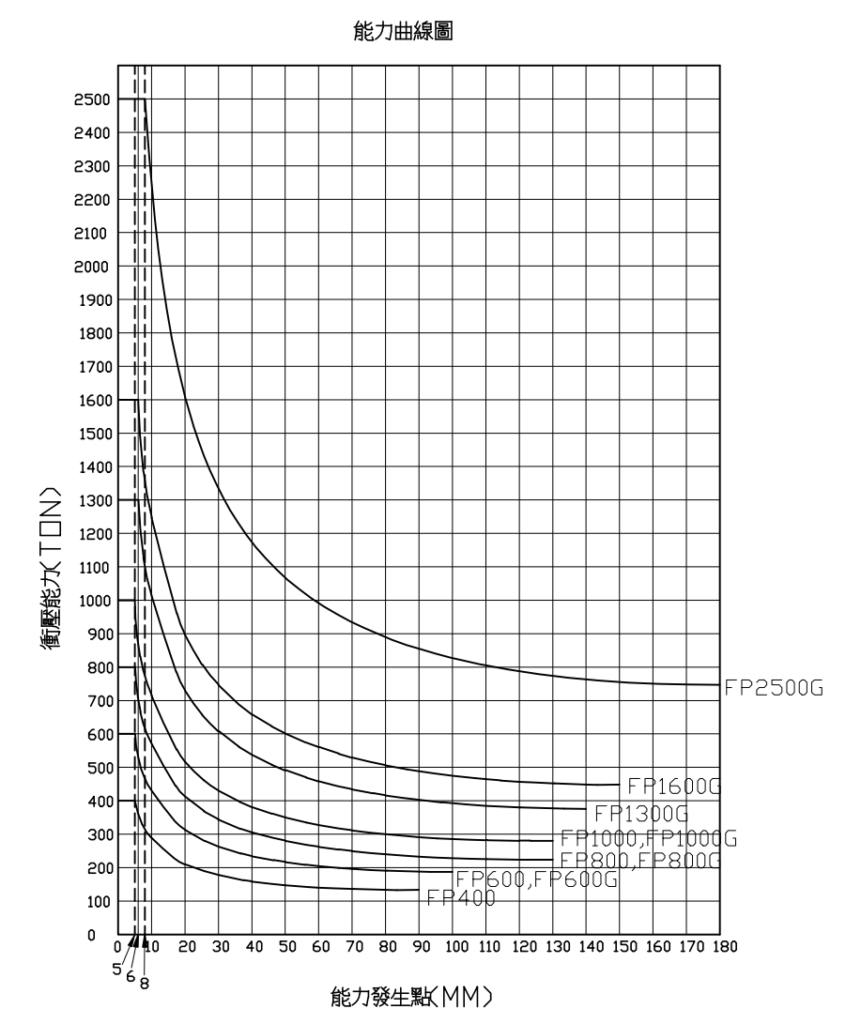

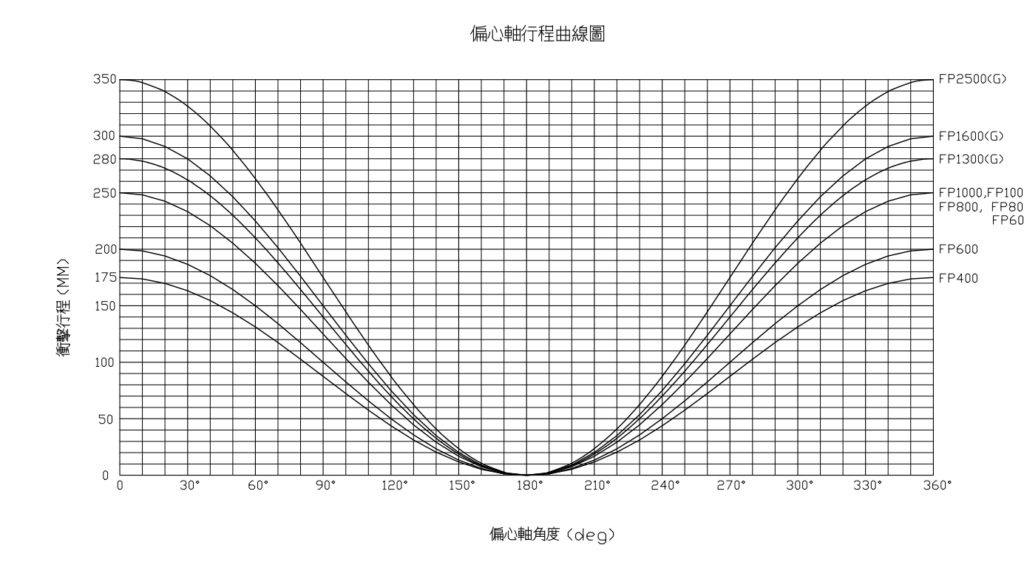

Tonnage @Energy ,stroke Curve

Reviews

There are no reviews yet.