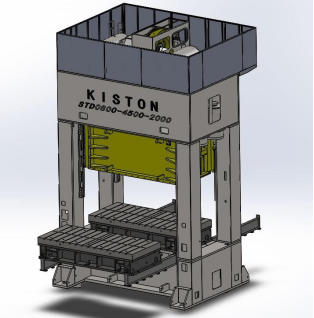

Product description

- Our Press model

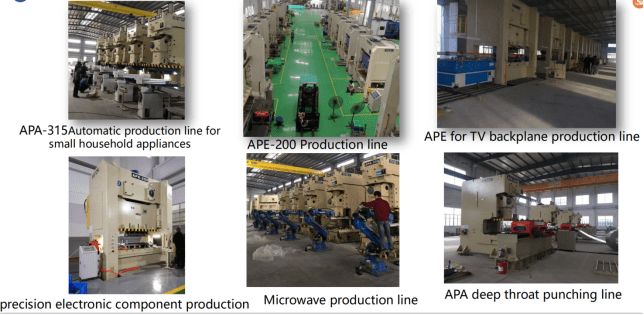

Our power press machine including APA precision C type steel frame press; KDL stroke adjustable model press , APC double crank precision steel frame press; APD semi-closed precision steel frame press; APE closed gantry double crank precision steel frame press; APH high speed gantry press; SH high speed precision press; S1-S4 Eccentric gear type large press, etc..

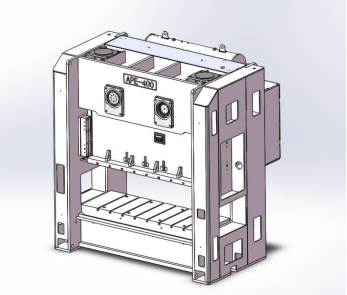

- APE model Specification : (other model please contact us )

| Name | APE-200 | APE-300 | APE-400 |

| Model | S TYPE | S TYPE | S TYPE |

| Capacity (Ton) | 200 | 300 | 400 |

| Rated tonnage point (mm) | 6 | 7 | 7 |

| Speed changing (s.p.m) | 20-50 | 20-35 | 20-30 |

| Stroke (mm) | 250 | 300 | 300 |

| Die height (mm) | 500 | 550 | 550 |

| Slide adjustment (mm) | 120 | 120 | 120 |

| Slide area (mm) | 1850X750 | 2100X900 | 2800X900 |

| Bolster area (mm) | 2200X940 | 2500X1000 | 3200X1000 |

| Main motor (kw.p) | VS18.5x 4 | VS30X4 | VS30x 4 |

| Slide adjust service (HP) | Electric driving | Electric driving | Electric driving |

| Air pressure (kg/cm2) | 6 | 6 | 6 |

- Machine configuration

| Item | Brief Description | |

| Machine Body | Basic Parts | Steel plate welded structure, through vibration aging treatment, the overall heat ageing annealing treatment. (Double aging treatment) |

| Bolster | basic parts | Made from Casting HT200,through annealing treatment |

| Crank | Basic Parts | Made from Forging, through flaw detection ,surface quenching, nitriding processing |

| Fly Wheel | Basic Parts | Casting HT200,Through Annealing Treatment |

| Worm | Basic Parts | Zinc-based alloys |

| Worm Gear | Basic Parts | Made from 45# steel |

| Connecting Rod | Basic Parts | Made from Ductile iron, cast iron, and throughnormalizing treatment |

| Ball Head and Screw | Basic Parts | Made From 45# steel, surface by Nitriding treatment |

| Balance Cylinder | Parts | Cylinder Body Inside Through Honing Processing |

| Machine body | Steel metal machine body, iron cast working table |

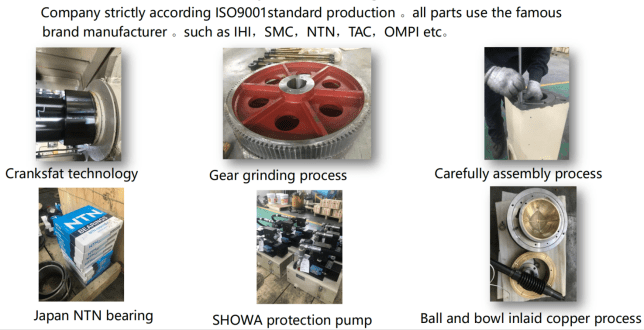

| Gears | Forging die gear grinding with Germany N1LES grinding machine; |

| Inverter | TECO ( Taiwan ) |

| Motor ` | TECO ( Taiwan ) |

| Double-solenoid valve | TACO ( JAPAN ) |

| CLUTCH | OMPI ( Italy ) |

| Over-load protector | KINGAIR ( Taiwan ) |

| Bearing | NSK ( Japan ) |

| Oil seals | NOK ( Japan ) |

| Contactor and other parts | Schneider |

| Air adapter | 3A ( Korea) |

| Nuts/screw and fastener | MaoYi ( Taiwan) |

- Detail parts production process:

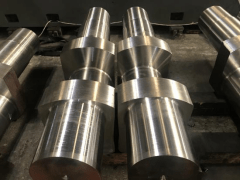

| Forging crank , complete one piece forging making , not welding type |  |

|

| Crank grinding , crank first going the lathe machine , then will use the grinding machine , one crank need take 7 hours grinding process

|

|

|

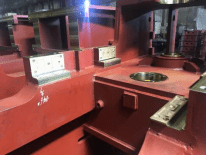

| Machine frame , first will use the plasma cutting machine cutting the steel plate , before welding frame , we will use the beveling machine beveling the steel first , then fully welding again , this is our specially process , will making the frame body more stronger , after going shot blasting , and painting |   |

|

| Advanced Equipments for machine body process

We use CNC floor type boring machine

|

|

|

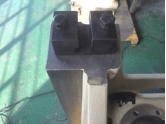

| High precision gear , keep machine running low noise

Made by Germany NILE Grinder

|

|

|

| For the ram assembly , every ram we stamp one code , to insure the assembly quality

|

|

|

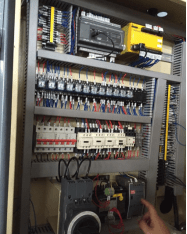

| All electrical parts as CE standard

Main Parts (Schneider)

|

|

|

| Customer reference in UK

Nico Manufacturing Ltd, 109 Oxford Road, Clacton-On-Sea, Essex. CO15 3TJ |

|

|

| Customer reference in CA

Future Steel Buildings Intl. Corp. 220 Chrysler Drive Brampton, Ontario Canada, L6S 6B6

|

|

|

- Company Honor

- Customer case

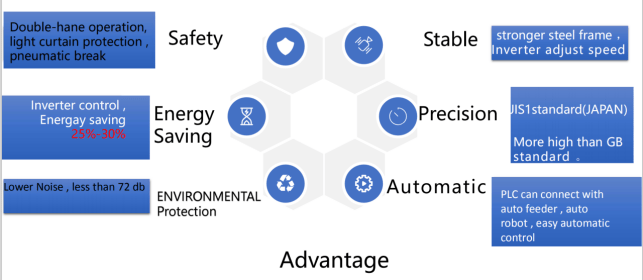

- Machine/ Company advantage

- adopts advanced SOLIDWORKS 3D solid model design technology;

- 3D design has the following significant advantages:

- Intuitive, easy to find space interference problems in the design, and greatly reduce errors in the design process;

- Improve work efficiency, easily and quickly import 3D into 2D, greatly improve the efficiency of engineers’ drawing;

- The borrowing of shared parts between models can greatly reduce the amount of repetitive work.

Reviews

There are no reviews yet.