Product description

Specification :

| Name | APC-110 | APC-160 | ||

| V | H | V | H | |

| Capacity (Ton) | 110 | 160 | ||

| Rated tonnage point (mm) | 5 | 3 | 6 | 3 |

| Speed changing (s.p.m) | 36-65 | 50-100 | 30-55 | 40-85 |

| Stroke (mm) | 180 | 110 | 200 | 130 |

| Die height (mm) | 400 | 435 | 450 | 485 |

| Slide adjustment (mm) | 100 | 100 | ||

| Bolster area (mm) | 1800X650X130 | 2000X760X150 | ||

| Slide area (mm) | 1400X500X70 | 1600X550X70 | ||

| Weight (Ton ) | 14.2 | 20 | ||

| Main motor (kw.p) | 11 | 15 | ||

| Name | APC-200 | APC-250 | ||

| V | H | V | H | |

| Capacity (Ton) | 200 | 250 | ||

| Rated tonnage point (mm) | 6 | 3 | 7 | 3.5 |

| Speed changing (s.p.m) | 25-45 | 35-70 | 20-35 | 35-60 |

| Stroke (mm) | 250 | 150 | 280 | 170 |

| Die height (mm) | 500 | 550 | 400 | 605 |

| Slide adjustment (mm) | 120 | 120 | ||

| Bolster area (mm) | 2400X840X170 | 2700X900X170 | ||

| Slide area (mm) | 1850X650X95 | 2100X700X96 | ||

| Weight (Ton ) | 27.5 | 45.5 | ||

| Main motor (kw.p) | 18.5 | 22 | ||

Machine configuration

| Standard Accessories | Optional Accessories | ||

| 1 | PLC + HMI | 1 | Die cushion |

| 2 | Dry clutch or wet clutch as option | 2 | Quick die change (Die lifter, die clamp, die arm etc.) |

| 3 | Miss feeding detector | 3 | Coil decoiling machine |

| 4 | Anti-vibration pads | 4 | Coil straightener |

| 5 | Auto grease lubrication | 5 | Coil servo feeder |

| 6 | Overrun protection device | 6 | Stamping dies(single stage die, progressive die, transfer die) |

| 7 | Photoelectric protection device/Light curtains | 7 | Automation/manipulator arms |

| 8 | Die height indicator | ||

| 9 | Motor inverter | ||

| 10 | Balancer | ||

| 11 | Cam switch | ||

| 12 | Knock-out device | ||

| 13 | Air ejector | ||

| 14 | Die light | ||

| 15 | Local voltage transformer | ||

| 16 | Maintenance tools and tool box | ||

Press Machine Components

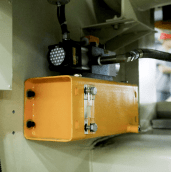

| Hydraulic overload protection pump

When the pressure of slider exceeds its specified pressure, the overload pump will relieve the pressure to protect the stressed part of press machine from damage.

|

|

| Inverter

It works mainly for speed regulation, convenient for mold installation and trial by operators as well as machine maintenance. |

|

| Auto grease lubrication device

It works under PLC control, providing lubrication for guide rails, crankshaft bearing bush, etc. without manual interference, realizing automatic lubrication |

|

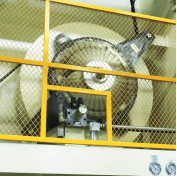

| Clutch and brake integrated

The function of clutch and brake is to control the movement and stop of slider, its sensitivity directly relates to safety issues, it works on the purpose of protecting the operators and press machine. |

|

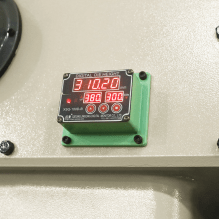

| Digital die height indicator

Die height display is an instrument to show the height of the die. It has upper and lower limits to protect the height of die within a certain range.

|

|

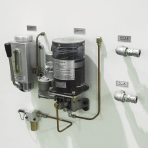

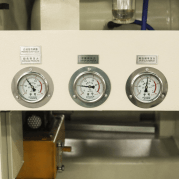

| Balancer and clutch pressure meter

The pressure of overload protection pump is generally adjusted at 0.4MPa, clutch and brake pressure at 0.6MPa, balancer pressure at 0.4MPa. |

|

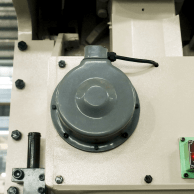

| Slide adjustment motor

The motor drives the slider, which moves up and down to adjust the distance between slider and working table. When the distance is adjusted well, motor stops working. |

|

| Touch screen

Multi language touch screen control system. It displays a series of press parameter, such as SPM (strokes per minute), electronic cam angle etc. You may set other corresponding data through this touch screen. |

|

| Hands operation panel

When operators start the machine, they need to press the left and right buttons at the same time, which is to avoid potential safety risks when operators start the button while operating the machine. |

|

Reviews

There are no reviews yet.