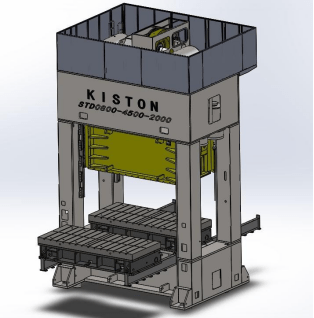

Product description

Punch press CNC single crank power press , controled by both PLC and hands operation.

Advanced technology CNC punch machine / C Frame Punching machine

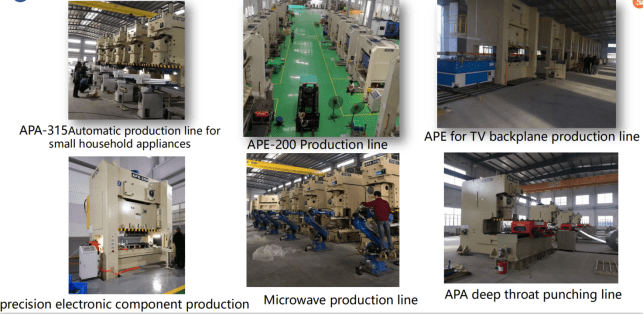

Our brand is KISTON, this type pneumatic press machine /punching machine we producing mainly about 25T, 35T, 45T, 60T, 80T, 110T, 160T, 200T, 260T, 315T,etc.

Specification :

| Name | APA-35 | APA-45 | APA-80 | APA-160 |

| Model | V type | V type | V type | V type |

| Capacity (Ton) | 35 | 45 | 80 | 160 |

| Rated tonnage point (mm) | 3.2 | 3.2 | 4 | 6 |

| Speed changing (s.p.m) | 40-120 | 40-100 | 35-80 | 20-50 |

| Stable speed (s.p.m) | 85 | 75 | 65 | 35 |

| Stroke (mm) | 70 | 80 | 150 | 200 |

| Die height (mm) | 220 | 250 | 400 | 450 |

| Slide adjustment (mm) | 55 | 60 | 80 | 100 |

| Slide area (mm) | 360x250x50 | 400x300x60 | 600 x 420 x 70 | 700 x 550 x 90 |

| Bolster area (mm) | 800x400x70 | 850x440x80 | 1000 x 550 x 90 | 1250 x 800 x 140 |

| Shank hole (mm) | 38.1 | 38.1 | 50 | 65 |

| Main motor (kw.p) | VS3.7X4 | VS5.5×4 | VS7.5 x 4 | VS15 x 4 |

| Slide adjust service (HP) | Manual operation | electric driving | ||

| Air pressure (kg/cm2) | 6 | 6 | 6 | 6 |

| Presses precision | GB(JIS) 1 class | |||

| Presses dimension (mm) | 1380x900x2400 | 1575x950x2500 | 1800 x 1180 x 3040 | 2315 x 1400 x 3810 |

| Presses weight (Tons) | 3ton | 3.8 ton | 7 ton | 14 ton |

| Die cusion capacity (Ton) | 2.3 | 2.3 | 3.6 | 10 |

| Stroke (mm) | 50 | 50 | 70 | 80 |

| Die cusion effective area (mm2) | 300×230 | 300×230 | 450 x 310 | 650 x 420 |

| Name | APA-200 | APA-200B | APA-260 | APA-315 |

| Model | V type | V type | V type | V type |

| Capacity (Ton) | 200 | 200 | 260 | 315 |

| Rated tonnage point (mm) | 6 | 6 | 7 | 7 |

| Speed changing (s.p.m) | 20-50 | 20-50 | 20-40 | 20-40 |

| Stable speed (s.p.m) | 35 | 35 | 30 | 30 |

| Stroke (mm) | 200 | 200 | 250 | 250 |

| Die height (mm) | 460 | 460 | 500 | 520 |

| Slide adjustment (mm) | 110 | 100 | 120 | 120 |

| Slide area (mm) | 850x630x90 | 850x550x90 | 950 x 700 x 100 | 950 x 700 x 100 |

| Bolster area (mm) | 1400x820x160 | 1350x820x140 | 1500 x 840 x 180 | 1500 x 840 x 180 |

| Shank hole (mm) | 65 | 65 | 65 | 65 |

| Main motor (kw.p) | VS18X4 | VS18x4 | VS22 x 4 | VS30 x 4 |

| Slide adjust service (HP) | electric driving | |||

| Air pressure (kg/cm2) | 6 | 6 | 6 | 6 |

| Presses precision | GB(JIS) 1 class | |||

| Presses dimension (mm) | 2615x1690x4075 | 2740x1620x3690 | 2780 x 1850 x 4470 | 2780 x 1870 x 4490 |

| Presses weight (Tons) | 23ton | 19ton | 32 ton | 34 ton |

| Die cusion capacity (Ton) | 14 | 10 | 14 | 14 |

| Stroke (mm) | 100 | 80 | 100 | 100 |

| Die cusion effective area (mm2) | 710×480 | 650×420 | 810 x 480 | 810 x 480 |

Machine configuration

| Item | Brief Description | |

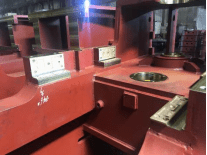

| Machine Body | Basic Parts | Steel plate welded structure, through vibration aging treatment, the overall heat ageing annealing treatment. (Double aging treatment) |

| Bolster | basic parts | Made from Casting HT200,through annealing treatment |

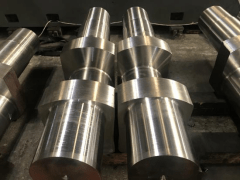

| Crank | Basic Parts | Made from Forging, through flaw detection ,surface quenching, nitriding processing |

| Fly Wheel | Basic Parts | Casting HT200,Through Annealing Treatment |

| Worm | Basic Parts | Zinc-based alloys |

| Worm Gear | Basic Parts | Made from 45# steel |

| Connecting Rod | Basic Parts | Made from Ductile iron, cast iron, and throughnormalizing treatment |

| Ball Head and Screw | Basic Parts | Made From 45# steel, surface by Nitriding treatment |

| Balance Cylinder | Parts | Cylinder Body Inside Through Honing Processing |

| Machine body | Steel metal machine body, iron cast working table |

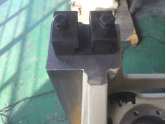

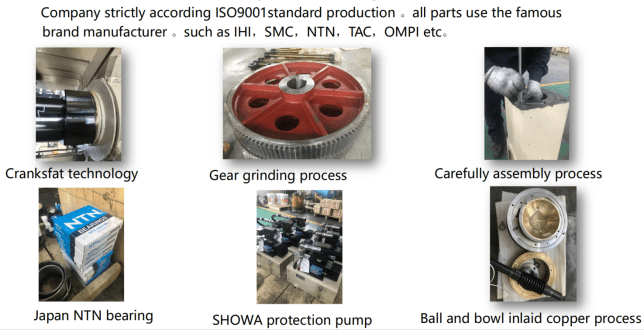

| Gears | Forging die gear grinding with Germany N1LES grinding machine; |

| Inverter | TECO ( Taiwan ) |

| Motor ` | TECO ( Taiwan ) |

| Double-solenoid valve | TACO ( JAPAN ) |

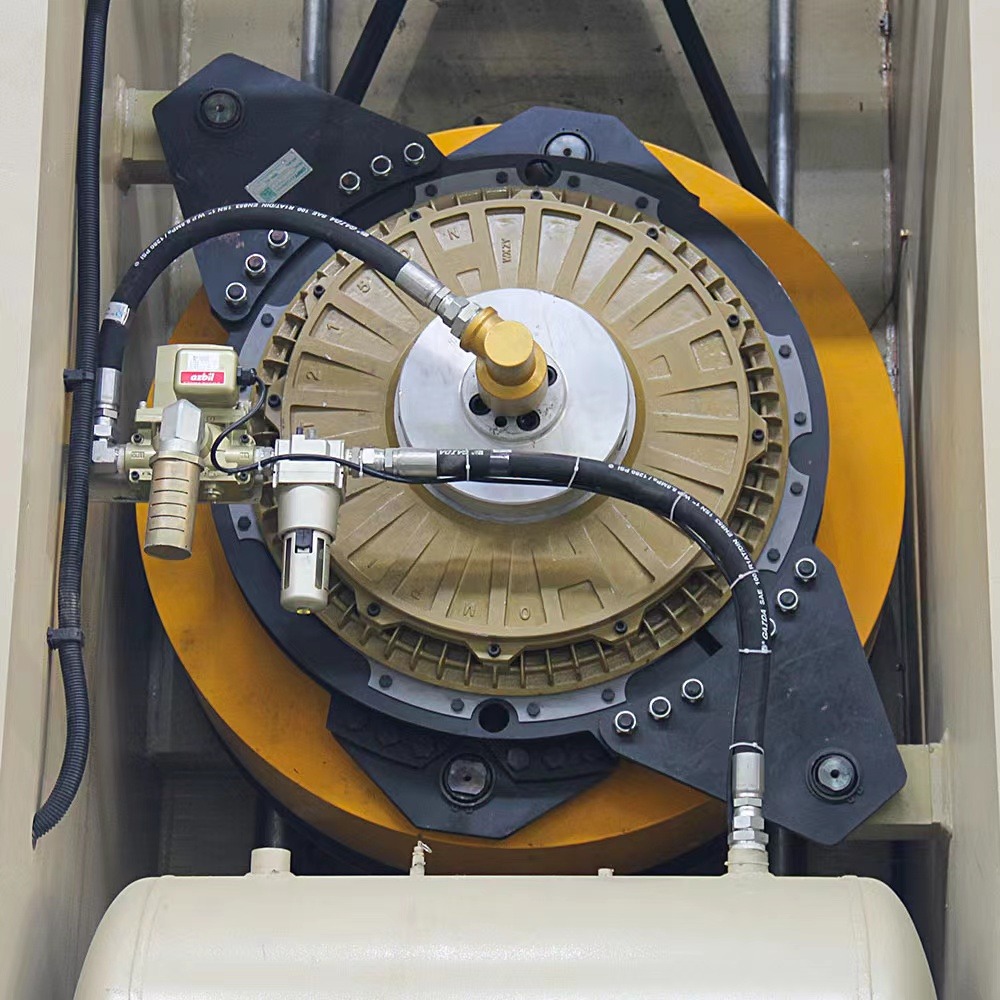

| CLUTCH | OMPI ( Italy ) |

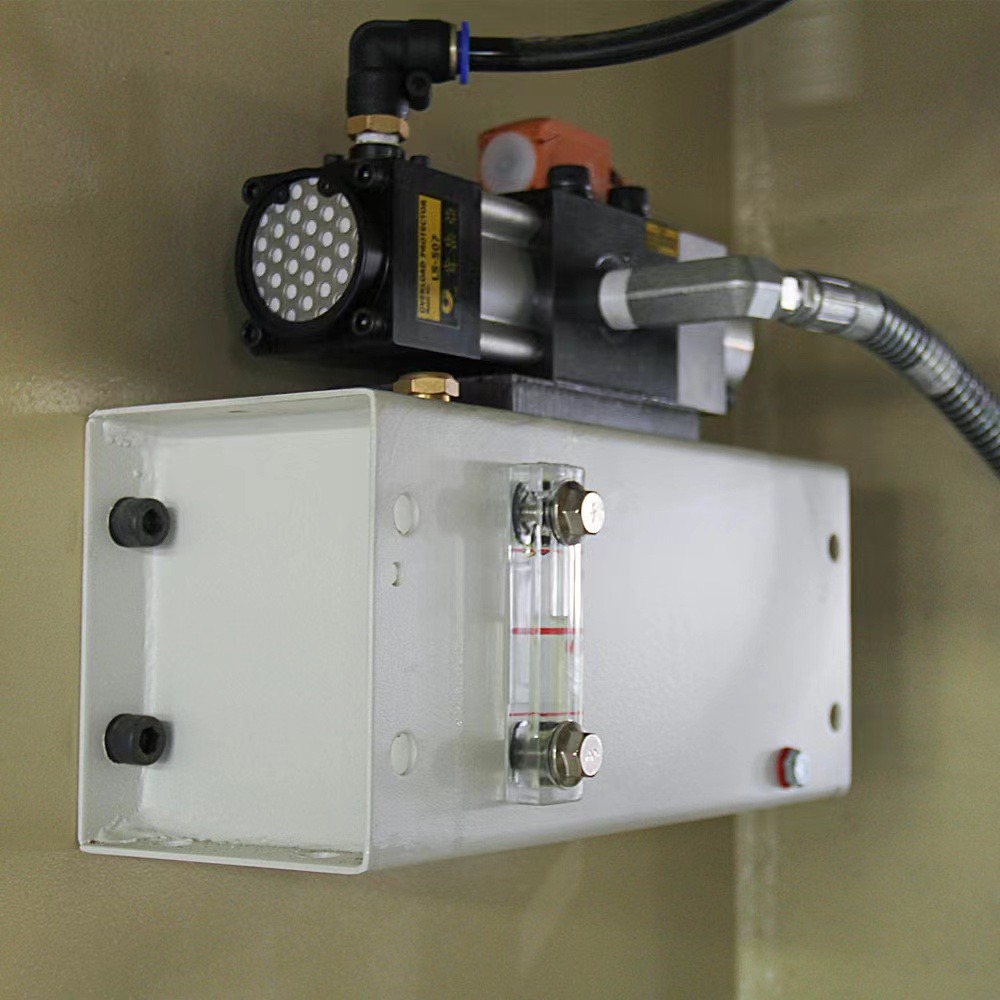

| Over-load protector | KINGAIR ( Taiwan ) |

| Bearing | NSK ( Japan ) |

| Oil seals | NOK ( Japan ) |

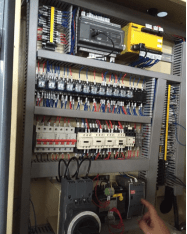

| Contactor and other parts | Schneider |

| Air adapter | 3A ( Korea) |

| Nuts/screw and fastener | MaoYi ( Taiwan) |

1. Detail parts production process:

| Forging crank , complete one piece forging making , not welding type |  |

|

| Crank grinding , crank first going the lathe machine , then will use the grinding machine , one crank need take 7 hours grinding process

|

|

|

| Machine frame , first will use the plasma cutting machine cutting the steel plate , before welding frame , we will use the beveling machine beveling the steel first , then fully welding again , this is our specially process , will making the frame body more stronger , after going shot blasting , and painting |   |

|

| Advanced Equipments for machine body process

We use CNC floor type boring machine

|

|

|

| High precision gear , keep machine running low noise

Made by Germany NILE Grinder

|

|

|

| For the ram assembly , every ram we stamp one code , to insure the assembly quality

|

|

|

| All electrical parts as CE standard

Main Parts (Schneider)

|

|

|

| Customer reference in UK

Nico Manufacturing Ltd, 109 Oxford Road, Clacton-On-Sea, Essex. CO15 3TJ |

|

|

| Customer reference in CA

Future Steel Buildings Intl. Corp. 220 Chrysler Drive Brampton, Ontario Canada, L6S 6B6

|

|

|

2. Company Honor

3. Customer case

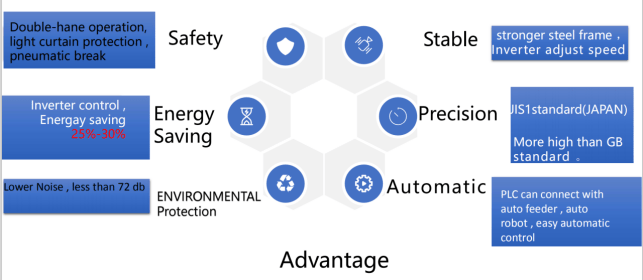

4. Machine/ Company advantage

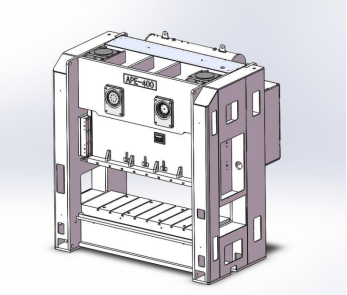

- adopts advanced SOLIDWORKS 3D solid model design technology;

- 3D design has the following significant advantages:

- Intuitive, easy to find space interference problems in the design, and greatly reduce errors in the design process;

- Improve work efficiency, easily and quickly import 3D into 2D, greatly improve the efficiency of engineers’ drawing;

- The borrowing of shared parts between models can greatly reduce the amount of repetitive work。

Reviews

There are no reviews yet.