Product description

Steel plate rolling machine description:

# steel plate rolling machine on this device for roller omnipotent steel plate rolling machine used for bending a certain thickness of the metal sheet at room temperature into a tube-shaped, curved or there is a taper of parts. The works by Rotary bending deformation. Upper roller can be moved up and down, and also move horizontally, so it does not need additional press and additional equipment to feed at a time, without having to turn to complete end pre-bending and bending of the plate features, as well as for correction of the workpiece. Using assistive devices can make the ends of sheets, and fewer remaining straight edge. Is oil, chemical, cement, shipbuilding, boilers, air, water, power transmission towers and other necessary equipment for the machinery and equipment manufacturing industry.

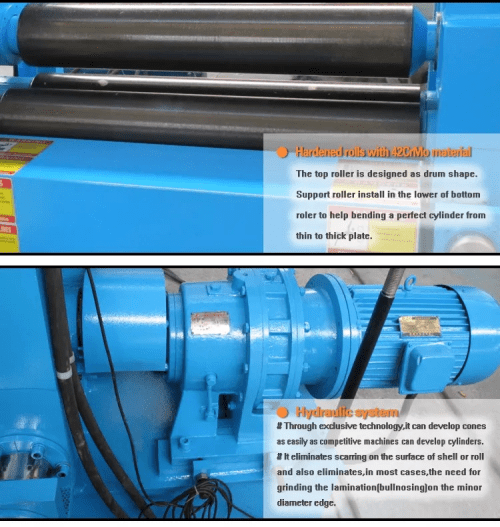

# The structure of this machine has four rollers, the upper roller is main drive, through the hydraulic motor provides the power to provide torque for coiled sheet; lower roller for vertical movement by hydraulic cylinder, to the clamping was coiled sheet, and the realization of non symmetric bending roll system.

# This machine is three rollers symmetries rolling mild steel or mild alloy steel under normal temperature condition (such as Q235, Q345, 16MnR, etc.) into cylinders.

# The machine is suitable for sheet metal bending, can be rolled round and arc and within a certain range of conical workpiece, and sheet metal bending function, the remaining straight edge, high work efficiency, and can be used crude the metal plate to be leveling.

# The upper roller is arranged the side roller device, the side roller is parallel to the roller axis for arc lifting motion, the side roller arc movement by the hydraulic cylinder.

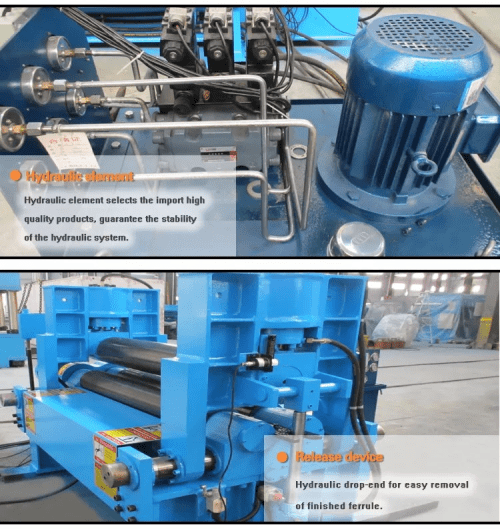

# Adopt the unique beforehand decompression technology, effectively avoid hydraulic impact, improve the lifetime of pipeline and the seal.

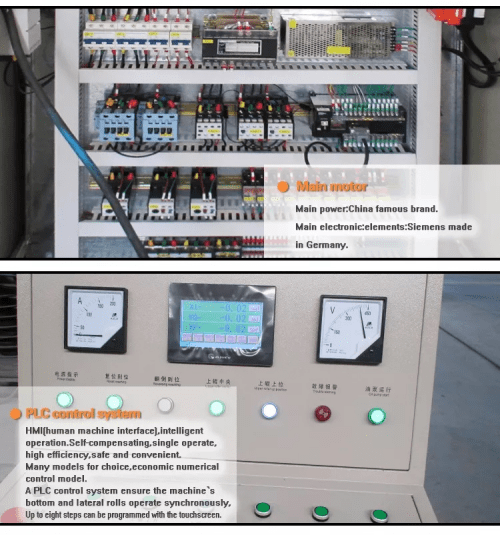

# Hydraulic element selects the import high quality products, guarantee the stability of the hydraulic system.

# All hydraulic system input, outlet are set with corresponding control point, easy for maintenance and fault inspection. Oil pump adopt underneath type, positive pressure oil absorption. At the same time the filter and liquid ometer are equipped with hair-device, it can automatic alarm the disturbance display. The hydraulic station is set independent outside of machine, easy for maintenance, also it’s away from the heat source.

# Production system strictly obey the international, line standard. The radius of bent tube is reasonable, and not less than 90 °, smooth transition, effectively avoid the impact and vibration

# System design full consideration of high efficiency and energy saving, reducing power waste, reduce heat source.

# Equipped with high precision oil absorption and oil return filter, in order to ensure the cleanliness of the oil system.

# Provide rolling machine hydraulic system common fault phenomenon and elimination method.

# In order to ensure the manufacturing quality of hydraulic system, the system produce according to the hydraulic professional manufacturers and National GB3766-83 “hydraulic system general technical conditions”

# The tank is cleaned by the shot blasting, pickling and surface cleaning, the walls is coated oil varnish to make sure the cleaning of tank. There is the air filter in the tank

Specification :

| Model | Maximum thickness (mm) | Maximum width(mm) | Yield limit(MPa) | Minimum diameter full capacity (mm) | Top roller diameter (mm) | Bottom roller diameter (mm) | Motor (kw) | Weight (kg) | Size (L.W.H) |

| (mm) | |||||||||

| W11Y50 x 3000 | 50 | 3000 | 245 | 2000 | 600 | 480 | 60 | 40000 | 9900 x 3100 x 3500 |

| W11Y30 x 3000 | 30 | 3000 | 245 | 1200 | 480 | 400 | 37 | 26000 | 7600 x 2200 x 2600 |

| W11Y25 x 2500 | 25 | 2500 | 245 | 900 | 340 | 280 | 22 | 18000 | 4660 x 1600 x 2100 |

| W11Y20 x 3000 | 20 | 3000 | 245 | 900 | 340 | 280 | 22 | 20000 | 5360 x 1600 x 2100 |

| W11Y12 x 3000 | 12 | 3000 | 245 | 700 | 280 | 220 | 18.5 | 12000 | 4800 x 1600 x 1700 |

| W11Y16 x 2500 | 16 | 2500 | 245 | 700 | 280 | 220 | 11 | 11000 | 4660 x 1420 x 1640 |

| W11Y16 x 3100 | 16 | 3100 | 245 | 850 | 340 | 280 | 15 | 13000 | 5260 x 1420 x 1640 |

| W11Y20 x 2500 | 20 | 2500 | 245 | 900 | 320 | 270 | 15 | 12000 | 4660 x 1420 x 1640 |

| W11-10 x 1300 | 10 | 1300 | 245 | 400 | 210 | 190 | 5.5/2.2 | 2425 | 2940 x 1100 x 1270 |

| W11-8 x 2500 | 8 | 2500 | 245 | 600 | 230 | 190 | 5.5/3 | 3485 | 4100 x 1100 x 1270 |

| W11-8X2000 | 8 | 2000 | 245 | 400 | 210 | 190 | 5.5/3 | 2890 | 3700 x 1100 x 1270 |

| W11-6 x 3100 | 6 | 3100 | 245 | 500 | 240 | 210 | 5.5/2.2 | 5390 | 4600 x 1150 x 1450 |

| W11-6X2500 | 6 | 2500 | 245 | 400 | 210 | 190 | 5.5/3 | 3195 | 4100 x 1100 x 1270 |

| W11-3 x 4100 | 3 | 4100 | 245 | 400 | 220 | 180 | 5.5/3 | 3500 | 5100 x 860 x 950 |

| W11-3 x 3100 | 3 | 3100 | 245 | 400 | 200 | 165 | 5.5/3 | 2720 | 4700 x 1000 x 1270 |

| W11-4 x 1300 | 4 | 1300 | 245 | 200 | 135 | 110 | 3/1.5 | 1060 | 2250 x 720 x 1300 |

| W11-4 x 1600 | 3 | 1600 | 245 | 200 | 135 | 110 | 3/1.5 | 1450 | 2600 x 720 x 1300 |

| W11-3 x 2000 | 3 | 2000 | 245 | 200 | 135 | 110 | 3/1.5 | 1650 | 2800 x 720 x 1300 |

Reviews

There are no reviews yet.